Quick Pallet Maker Example - Pasting Box Data for Pallet Loads

In this example we will show you how to paste the box data from a spreadsheet or a text file in which the data is delimited by tabs into the input window. We also explain how the different calculation options in the box shipment calculation pull-down menu work.

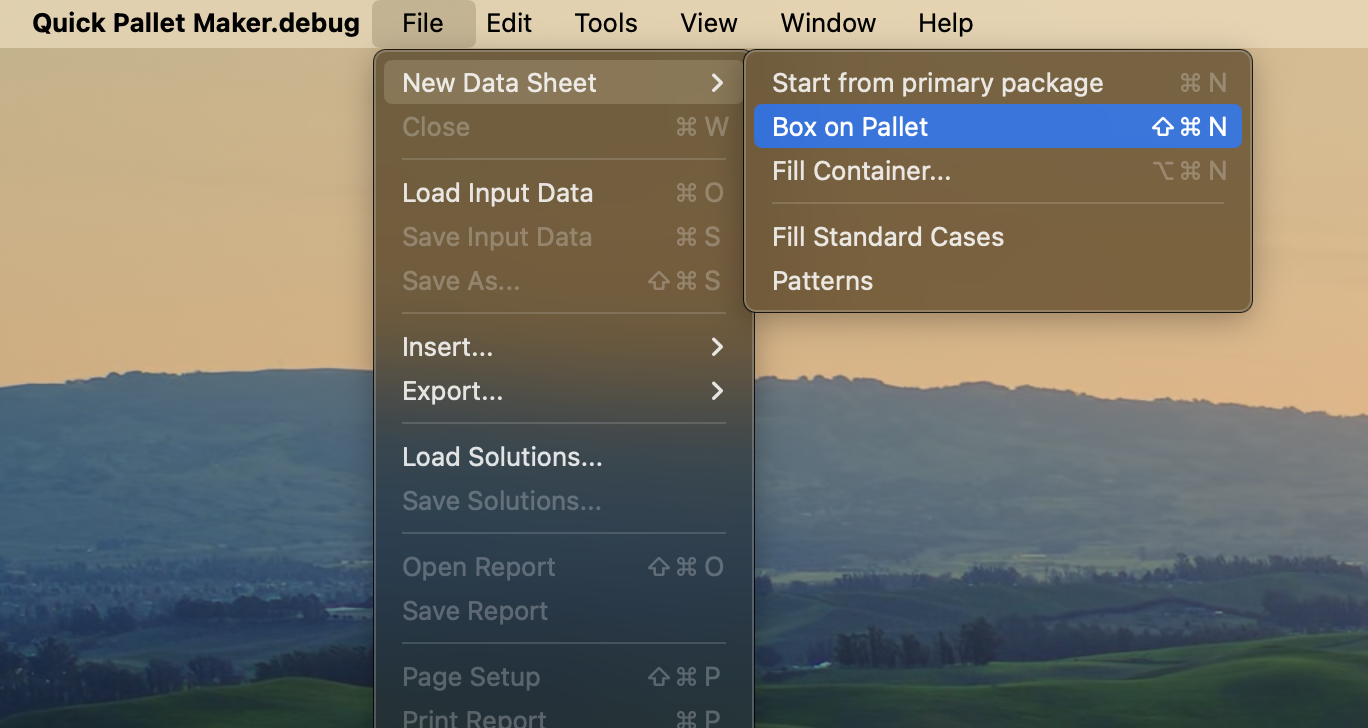

The first step is to open a new document window starting from box dimensions, using the Tools > New Data Sheet > Box on Pallet command.

New Data Sheet - Start from Box

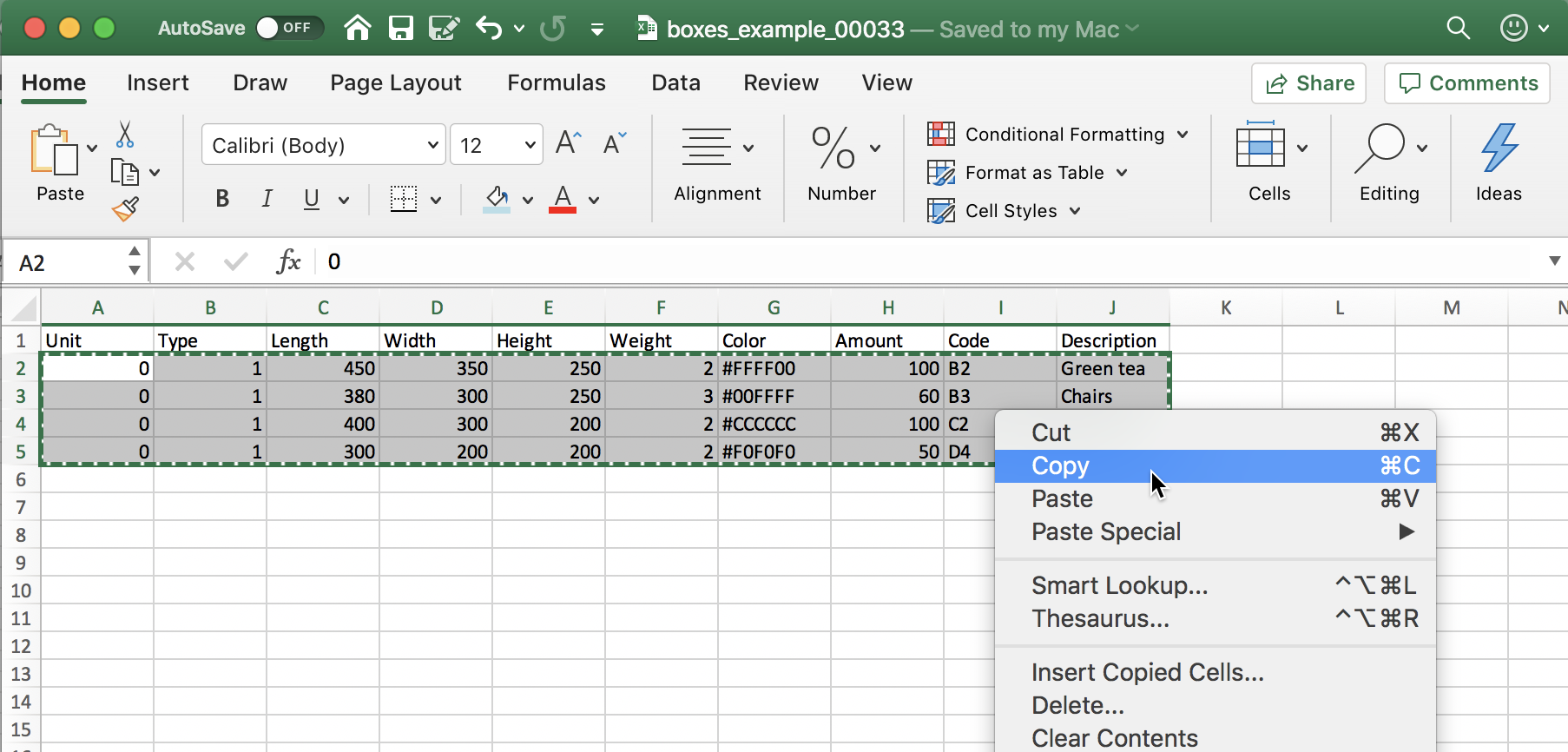

Go to the spreadsheet (such as Excel) or from any text file that contains columns separated by tabs and copy the data. The order of the columns is the following:

You can also download the example data by clicking here.

- Unit (write 0 for mm/kg, 1 for cm/kg or 2 for inches/pounds).

- Type (fill this column with the value 1 assigned to boxes).

- Length.

- Width.

- Height.

- Weight.

- Color (hexadecimal).

- Amount.

- Code (optional).

- Description (optional)

You can also download the example data by clicking here.

Copy from Spreadsheet

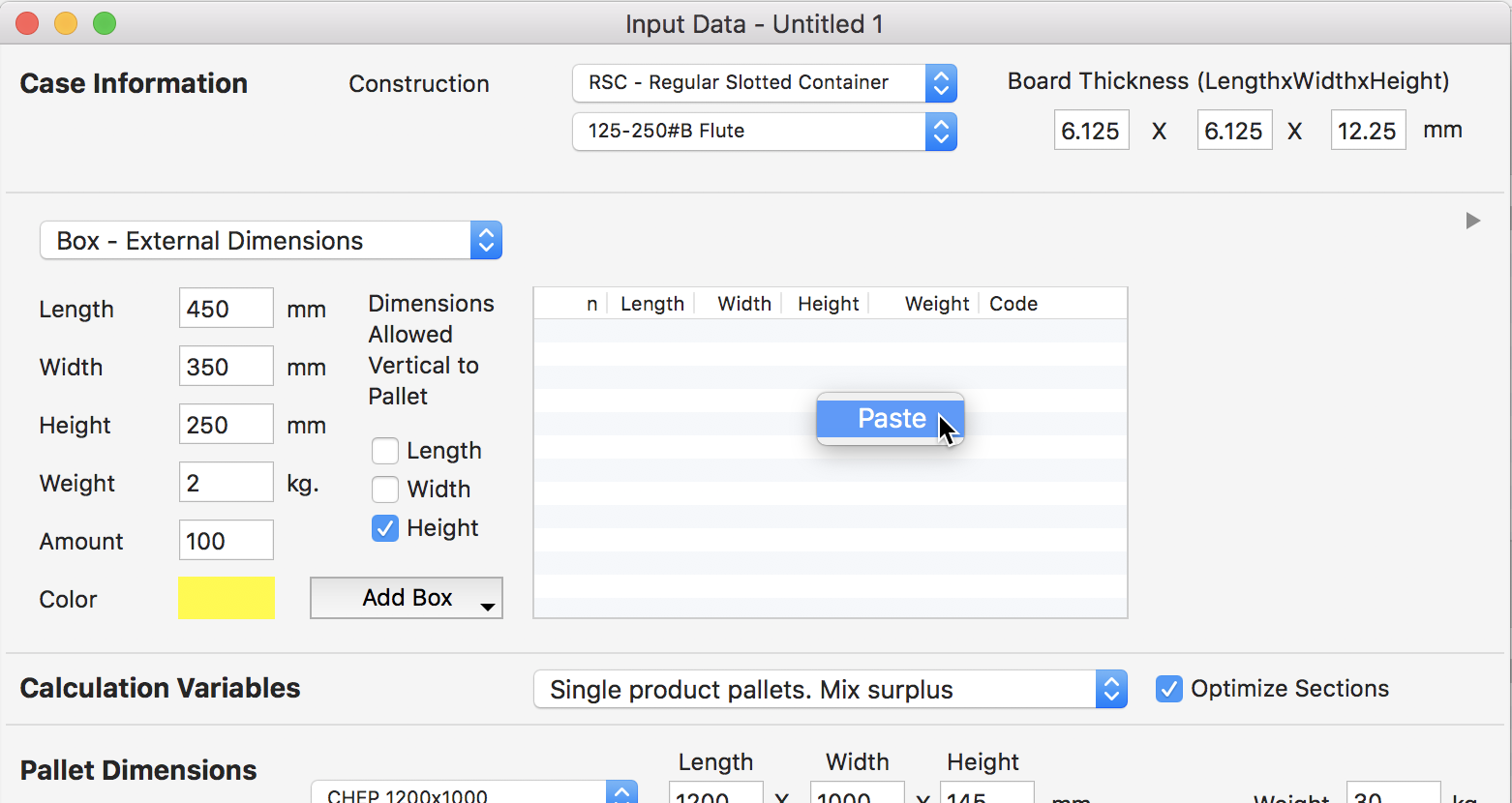

Paste the data in the input window by right-clicking on the central table and then choosing Paste.

Paste onto QPM

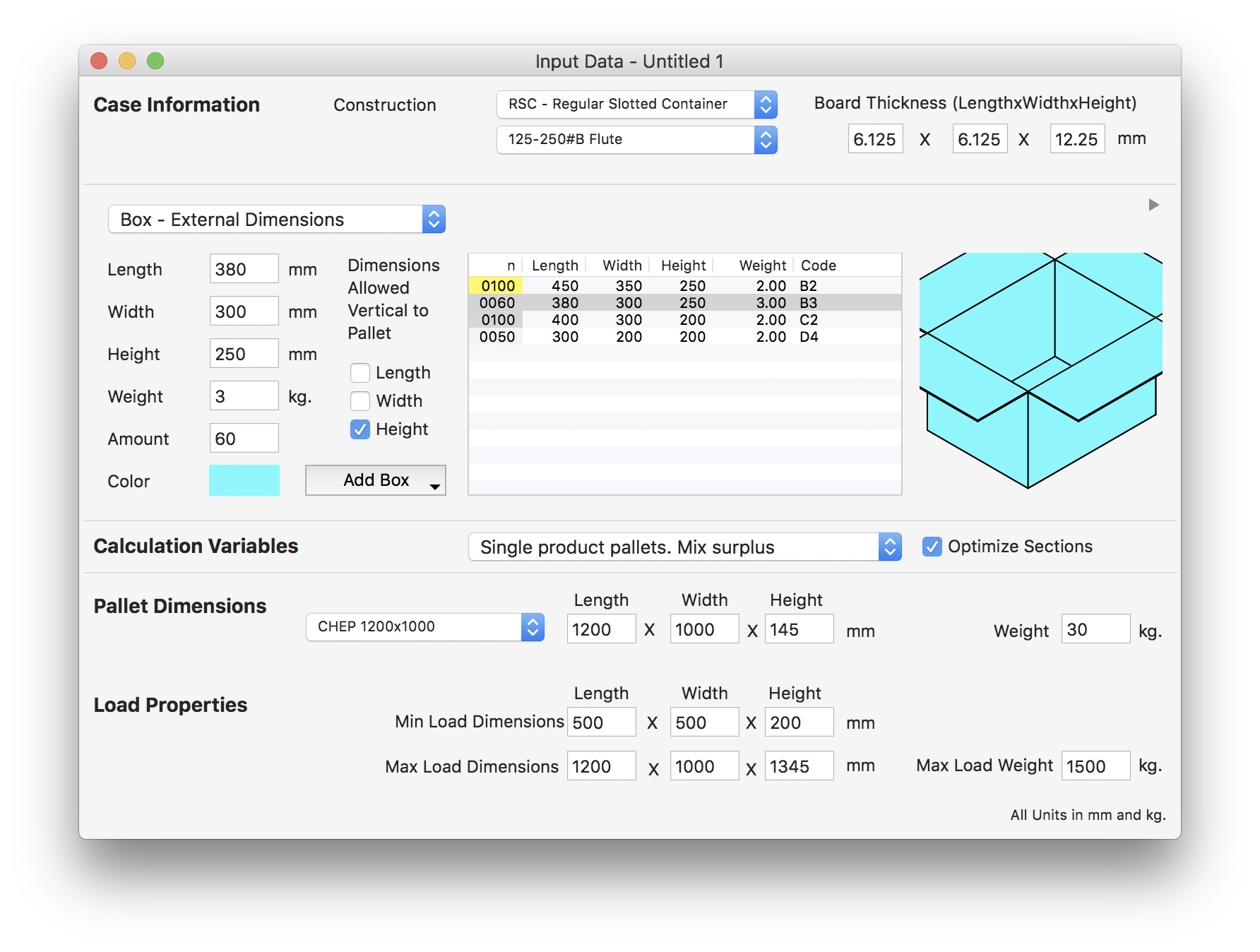

The box list should appear in the middle of the window. In the pulldown menu below, we will leave the default calculation mode, which is Single Product Pallets. Mix Surplus. What this does is try to create as many single-product pallets as possible, then create one or more pallets with the items that did not fit for each one of these pallets. We use the default 1200x1000 pallet with a maximum height of 1345 mm.

Box List

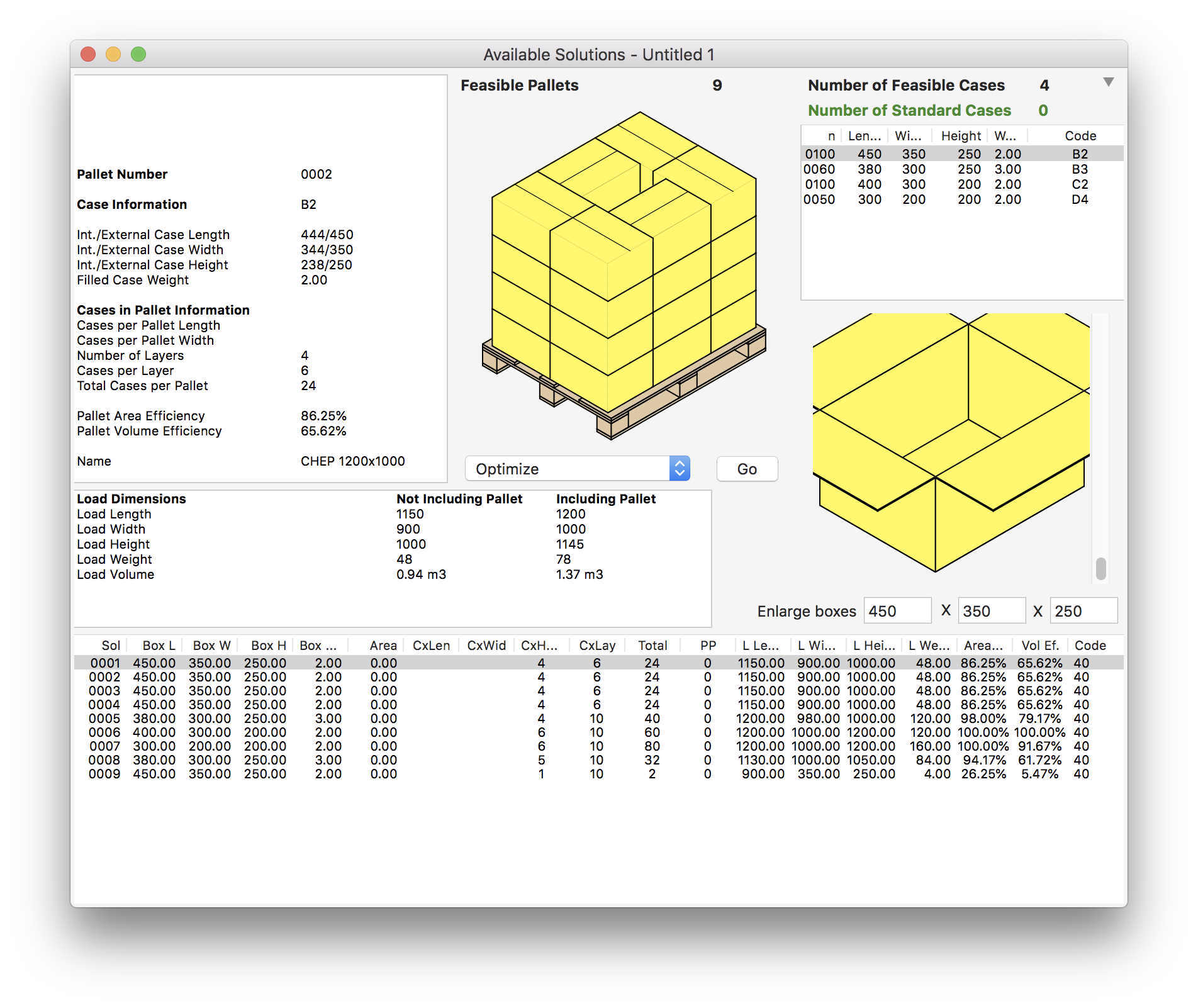

We use the Tools > Calculate Box Shipment command and obtain a list of 9 pallets.

Available Solutions

Now we use Tools > Change Data to go back to the input window. There, we will change the calculation option to Mix all products, and select Tools > Calculate Box Shipment.

Mix All Products

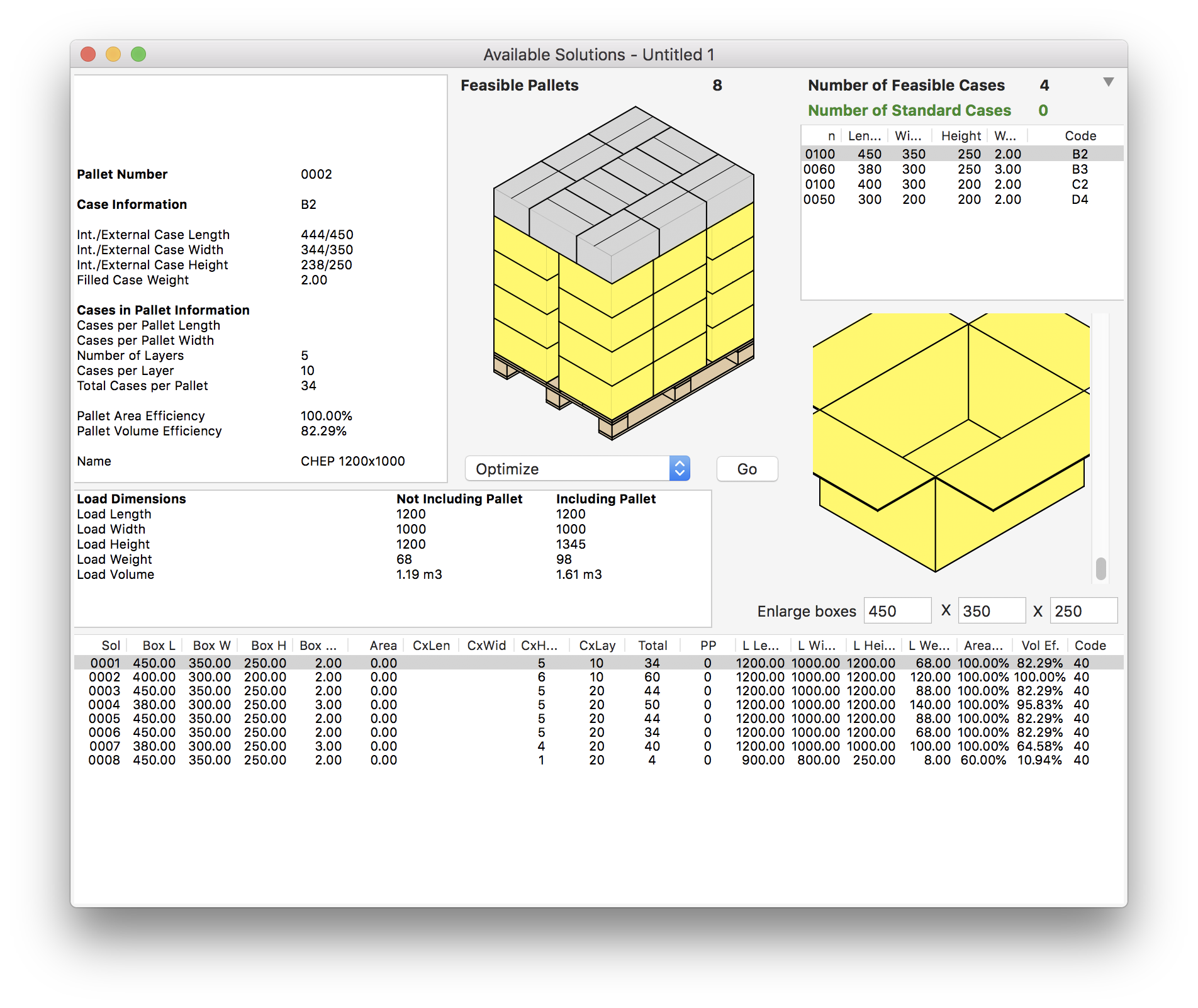

This will now create a shipment of 8 pallets. Please note that although we used one pallet less than the previous calculation mode, all of them are mixed, which means that the "picking" process in which pallets are manually loaded, will have to occur with all 8 of them, instead of just the last ones. Many times, the full pallets are already available in that way in the warehouse.

Available Solutions

Now we use Tools > Change Data again to go back to the input window. There, we will change the calculation option to Strict single-product pallets. No mixing., and select Tools > Calculate Box Shipment.

Strict single-product pallets

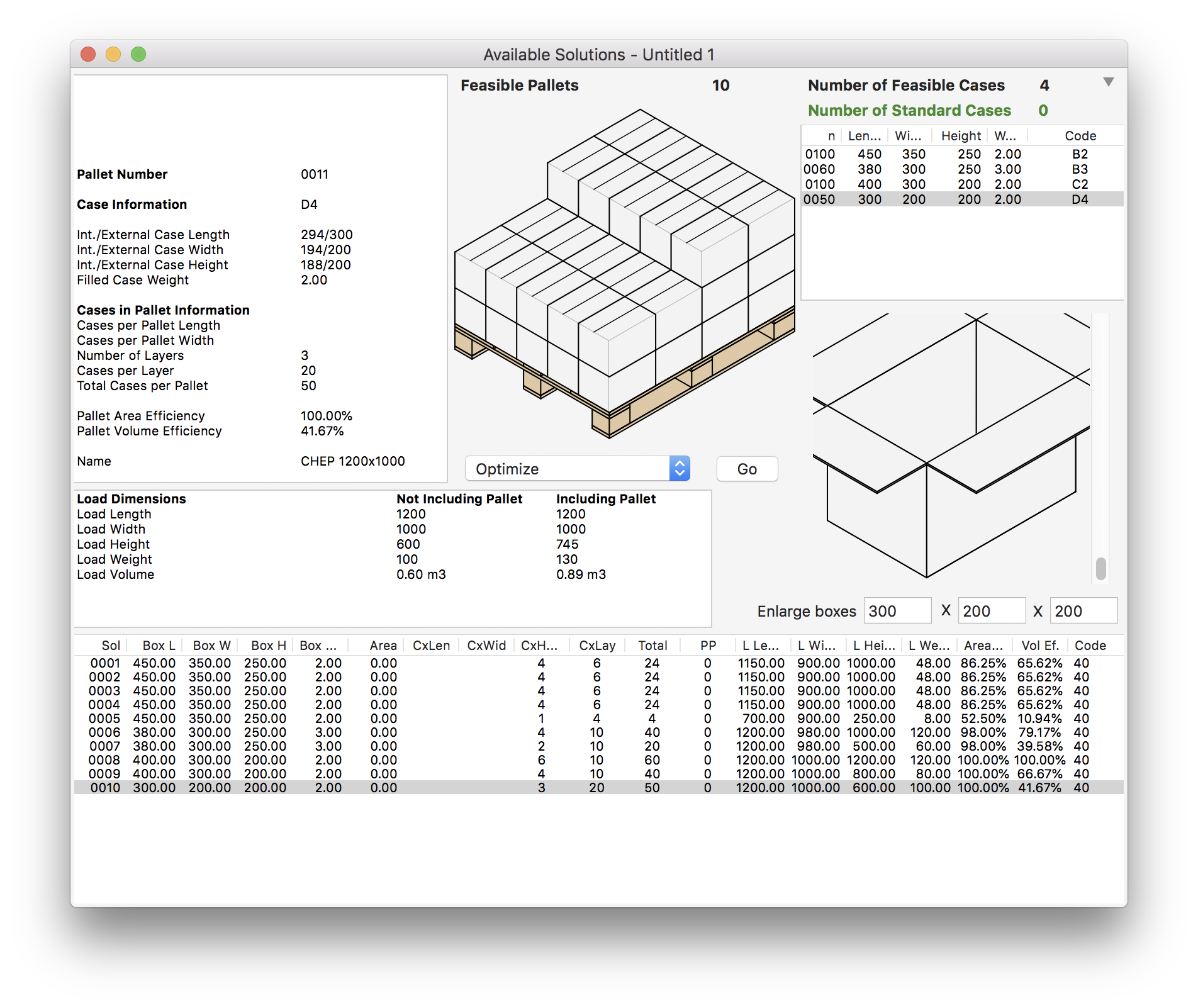

This option produces the least efficient type of shipment because it doesn't mix more than one product per pallet. Note that we need now 10 pallets to ship the same load.

Available Solutions

Watch the video

This example is also available as a YouTube video.YouTube Video